OSP (Organic Solderability Preservative)

Shikoku's OSP is contributing to electronic industry. We are manufacturer of imidazole which is an active ingredient of OSP and also developed the first OSP in the world .

Product list

| Glicoat | Glicoat-SMD | |||||||

|---|---|---|---|---|---|---|---|---|

| T | E series | F2 series | F3 F3PLUS |

|||||

| E3 | EX | F2 | F2(LX) | F2(LX)PK | ||||

| Process | 30℃ | 40℃ | 30℃ | 40℃ | 40℃ | 40℃ | 40℃ | |

| 10~20sec | 30sec | 20〜30sec | 60sec | 60sec | 60sec | 60sec | ||

| Active ingredient |

Alkyl Imidazole |

Alkyl benz Imidazole |

Imidazole A | Imidazole B | ||||

| Heat resistance | △ | △ | △ | ○ | ○ | ○ | ◎ | |

| Selective gold compatibility |

○ | ○ | ○ | ○ | ||||

| Advantage |

|

|

|

|

|

|||

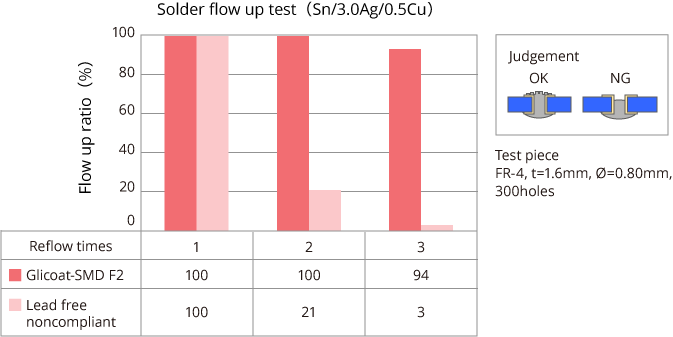

Glicoat-SMD F2

For lead-free solder

Glicoat-SMD F2 is de facto standard OSP to give excellent solder paste spreadability as well as solder flow-up in conjunction with lead-free solder.

Advantages

-

-

Glicoat-SMD F2 with high heat resistance shows excellent solderpaste spreadability as well as solder flow-up

-

More economical for running cost than metal surface finishes

-

Much higher solder joint strength compared with Gold plating

-

Safety and Environmentally-friendly, because of aqueous solution

-

Solderability

OSP(Organic Solderability Preservative)

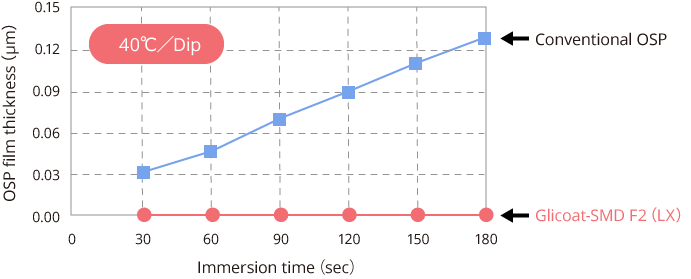

Glicoat-SMD F2(LX)

For lead-free solder and selective gold

Glicoat-SMD F2(LX) is de fact standard OSP to give excellent solder paste spreadability as well as solder flow-up in conjunction with lead-free solder. No OSP deposition on gold surface only on copper, it is suitable for copper and gold mixed selective gold PWBs.

Advantages

-

-

Excellent heat-resistance to stand multiple heat cycles same as F2 quality

-

Unnecessary controlling copper ion concentration

-

Unnecessary special specification for OSP treating line

-

OSP coating on gold

OSP for IC substrate

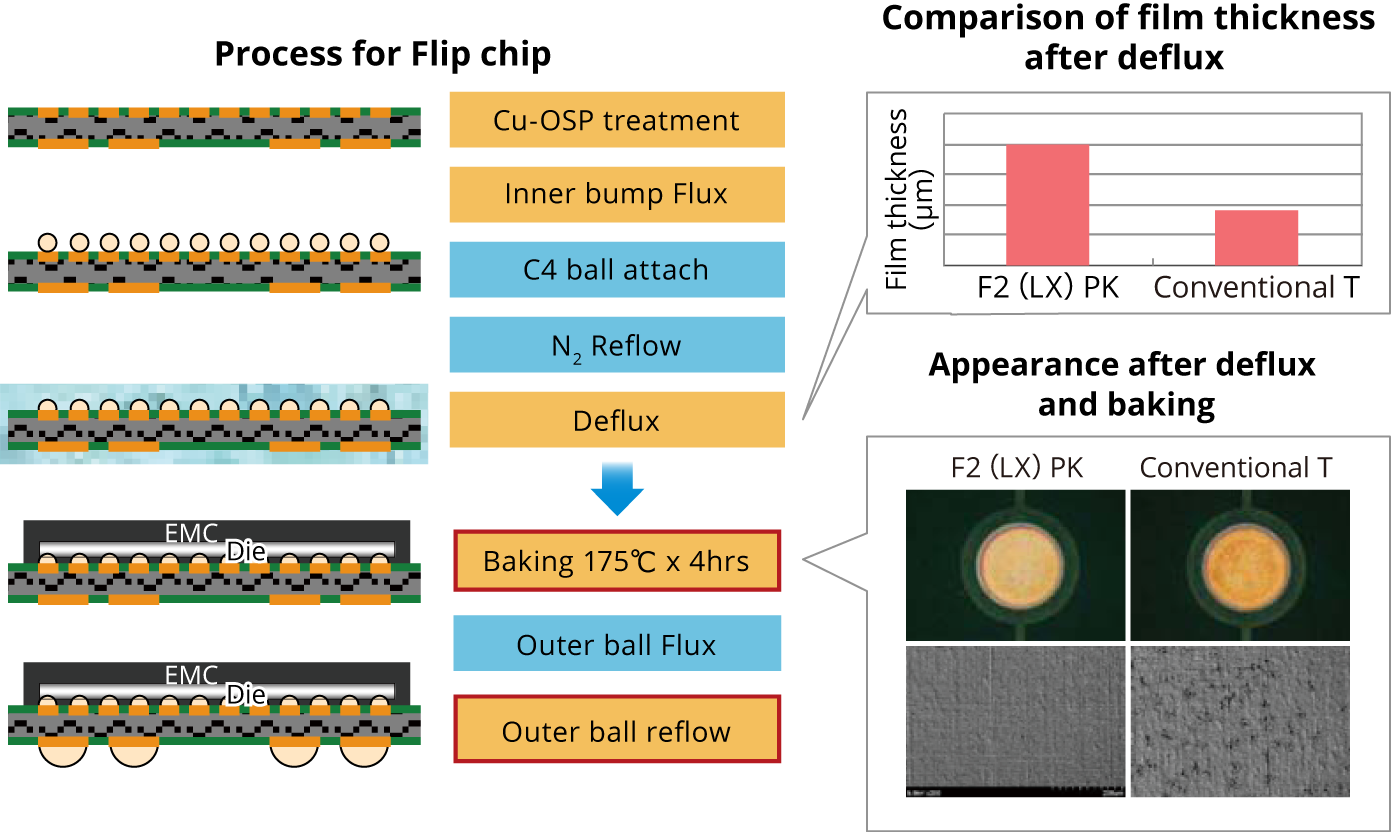

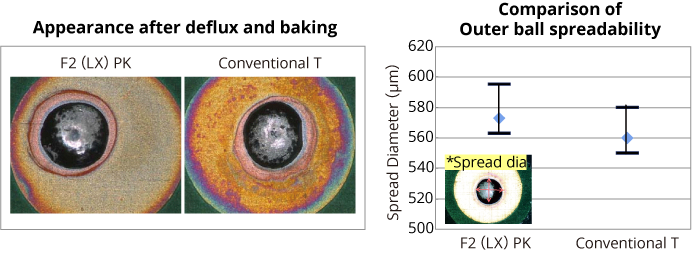

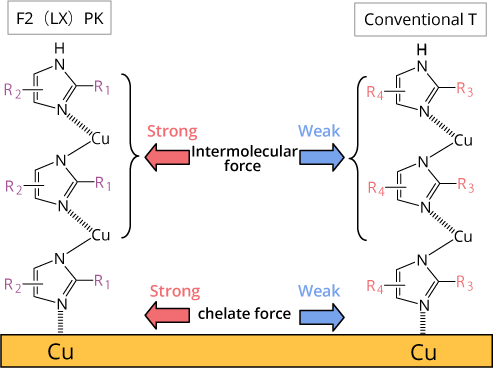

Glicoat-SMD F2(LX)PK

Glicoat-SMD F2(LX)PK is designed for IC substrate with excellent properties even after severe assembling conditions. It's widely used for Wire bonding type as well as Flip chip type, because of better solder joint strength than gold plating.

Advantages

-

-

Keep good appearance on outer pads even exposed by deflux solution for inner bump flux cleaning

-

Examine the optimum compatibility with inner / outer ball flux and deflux solution to minimize missing ball

-

OSP for Automotive PWB

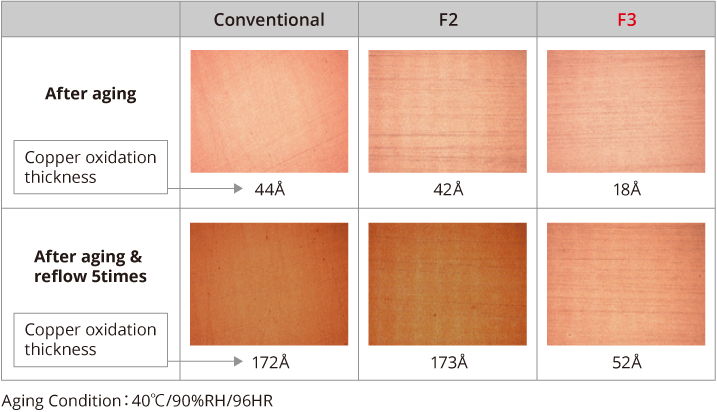

Glicoat-SMD F3

F3 shows excellent performance in terms of copper oxidation and humidity protection for longer shelf life, because of higher density organic layer than conventional OSPs.

Advantages

-

-

F3 gives longer shelf life and holding time the same as metal surface finishes

-

F3 gives excellent solderability, because of less oxidation and discoloration on copper surface after reflows

-

F3 is more economical for running cost than metal surface finishes

-

Property

Copper Discoloration